Drill Rig Matching Equipment

-

AC Variable Frequency Drive Drawworks

The main components of drawworks are AC variable frequency motor, gear reducer, hydraulic disc brake, winch frame, drum shaft assembly and automatic driller etc, with high gear transmission efficiency.

-

Mechanical Drive Drawworks on Drilling Rig

Drawworks positive gears all adopt roller chain transmission and negative ones adopt gear transmission. Driving chains with high accuracy and high strength are forced lubricated.

-

Swivel on Drilling Rig transfer drill fluid into drill string

The drilling Swivel is the main equipment for the rotary circulation of the underground operation. It is the connection between the hoisting system and the drilling tool, and the connection part between the circulation system and the rotating system. The upper part of the Swivel is hung on the hookblock through the elevator link, and is connected to the drilling hose by the gooseneck tube. The lower part is connected with the drill pipe and the downhole drilling tool, and the whole can be run up and down with the traveling block.

-

DC Drive Drawworks of Drilling Rigs High Load Capacity

Bearings all adopt roller ones and shafts are made of premium alloy steel. Driving chains with high accuracy and high strength are forced lubricated. The main brake adopts hydraulic disc brake, and the brake disc is water or air cooled. The auxiliary brake adopts electromagnetic eddy current brake(water or air cooled) or pneumatic push disc brake.

-

Crown Block of Oil/Gas Drilling Rig with Pulley and Rope

The sheave grooves are quenched to resist wear and extend its service life. The kick-back post and rope guard board prevent the wire rope from jumping out or falling out of the sheave grooves. Equipped with safety chain anti-collision device. Equipped with a gin pole for repairing the sheave block.

-

Hook Block Assembly of Drill Rig high weight lifting

The hook block adopt the integrated design. The traveling block and the hook are connected by the intermediate bearing body, and the big hook and the cruiser can be separately repaired.

-

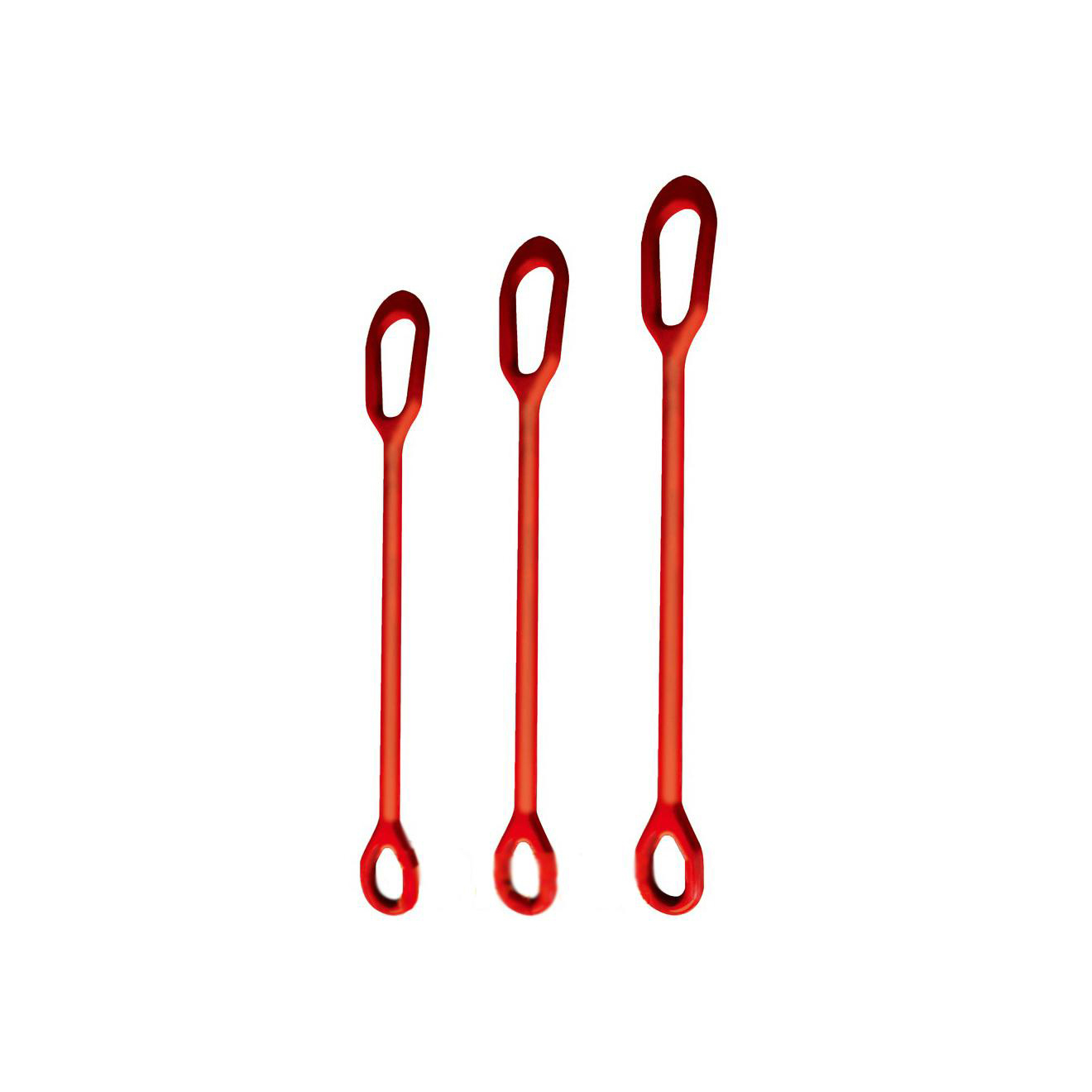

Elevator Link for hanging Elevator from TDS

Designing and manufacturing conform to API Spec 8C standard and SY/T5035 relevant technical standards etc.;

-

Traveling Block of oil drilling rigs high weight lifting

The Traveling Block is an important key equipment in the workover operation. Its main function is to form a pulley block by the sheaves of the Traveling Block and the mast , double the pulling force of the drilling rope, and bear all the downhole drill pipe or oil pipe and workover instruments through the hook.

-

F Series Mud Pump for oil field fluid control

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc.

-

3NB Series Mud Pump for oil field fluid control

3NB series mud pump includes:3NB-350, 3NB-500, 3NB-600, 3NB-800, 3NB-1000, 3NB-1300, 3NB-1600, 3NB-2200. 3NB series mud pumps are inclusive of 3NB-350, 3NB-500, 3NB-600, 3NB-800, 3NB-1000, 3NB-1300, 3NB-1600 and 3NB-2200.

-

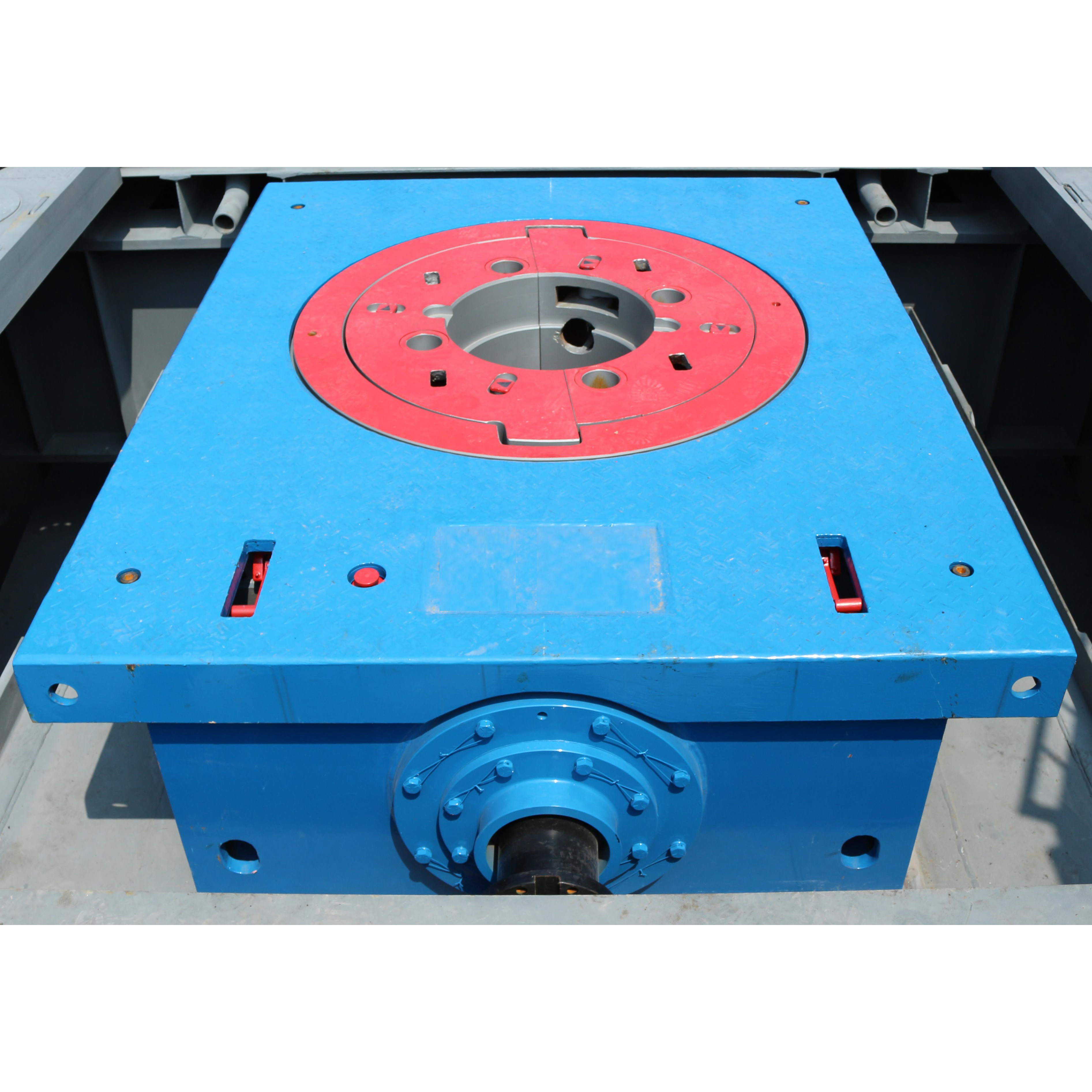

Rotary Table for Oil Drilling Rig

The transmission of rotary table adopts spiral bevel gears which have strong bearing capacity, smooth operation and long service life.