Elevator Link for hanging Elevator from TDS

• Designing and manufacturing conform to API Spec 8C standard and SY/T5035 relevant technical standards etc.;

• Select high-class alloy steel die to forge molding;

• Intensity check uses finite element analysis and electrical measuring method stress test. There are one-arm elevator link and two-arm elevator link;

Adopt two-stage shot blasting surface strengthening technology.

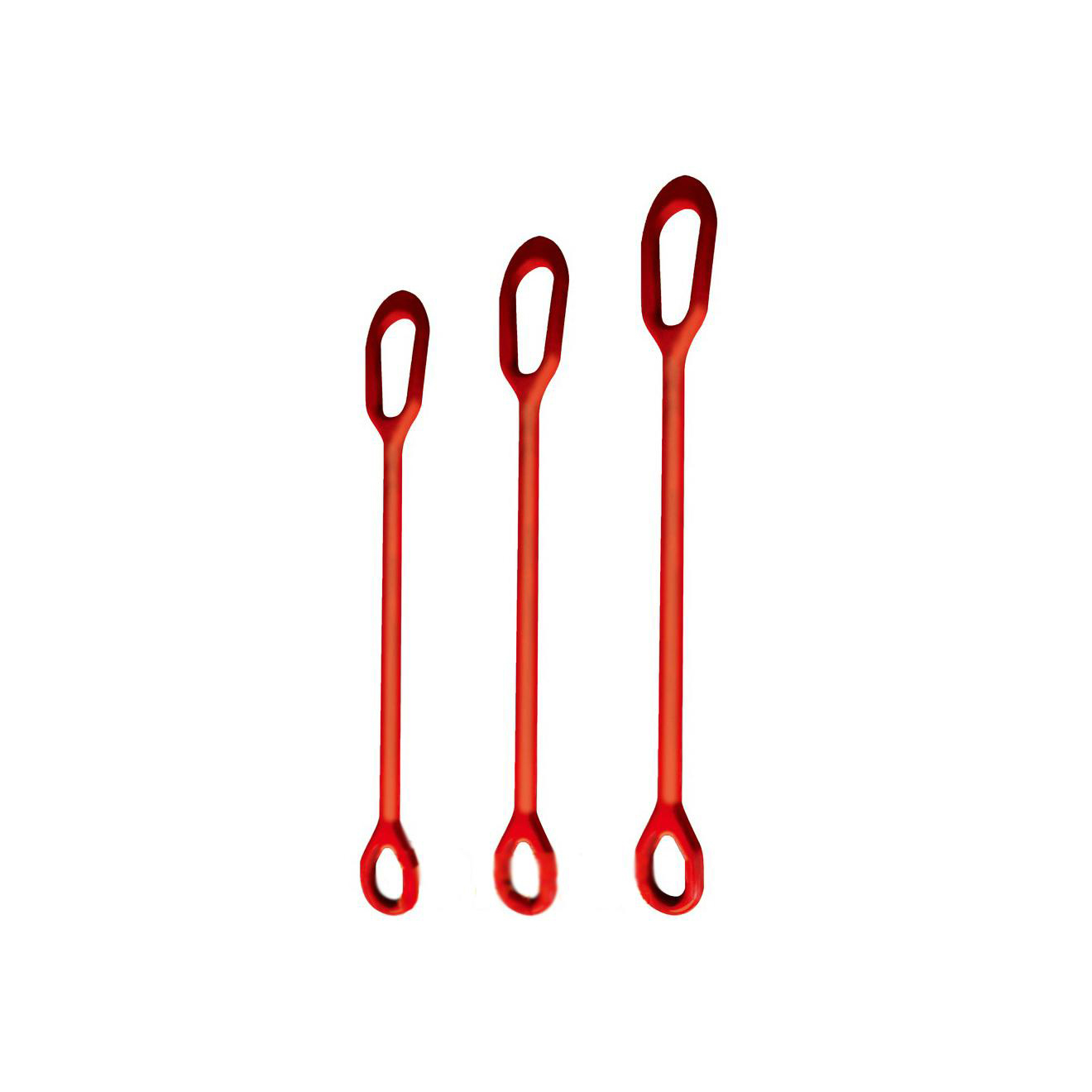

One-arm Elevator Link

|

Model |

Rated load (sh.tn) |

Standard working length mm(in) |

|

DH50 |

50 |

1100(43.3) |

|

DH75 |

75 |

1500(59.1) |

|

DH150 |

150 |

1800(70.9) |

|

DH250 |

250 |

2700(106.3) |

|

DH350 |

350 |

3300(129.9) |

|

DH500 |

450 |

3600 (141.7) |

|

DH750 |

750 |

3660(144.1) |

Two-arm Elevator Link

|

Model |

Rated load(sh.tn) |

Standard working length mm(in) |

|

SH75 |

75 |

1500(59.1) |

|

SH100 |

100 |

1500(59.1) |

|

SH150 |

150 |

1700(66.9) |

Write your message here and send it to us