Hot-Selling Downhole Motor - Downhole Jar / Drilling Jars (Mechanical / Hydraulic) – VS

Hot-Selling Downhole Motor - Downhole Jar / Drilling Jars (Mechanical / Hydraulic) – VS Detail:

1. [Drilling]

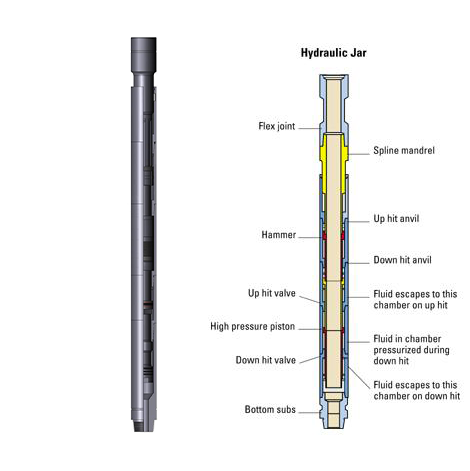

A mechanical device used downhole to deliver an impact load to another downhole component, especially when that component is stuck. There are two primary types, hydraulic and mechanical jars. While their respective designs are quite different, their operation is similar. Energy is stored in the drillstring and suddenly released by the jar when it fires. The principle is similar to that of a carpenter using a hammer. Kinetic energy is stored in the hammer as it is swung, and suddenly released to the nail and board when the hammer strikes the nail. Jars can be designed to strike up, down, or both. In the case of jarring up above a stuck bottomhole assembly, the driller slowly pulls up on the drillstring but the BHA does not move. Since the top of the drillstring is moving up, this means that the drillstring itself is stretching and storing energy. When the jars reach their firing point, they suddenly allow one section of the jar to move axially relative to a second, being pulled up rapidly in much the same way that one end of a stretched spring moves when released. After a few inches of movement, this moving section slams into a steel shoulder, imparting an impact load. In addition to the mechanical and hydraulic versions, jars are classified as drilling jars or fishing jars. The operation of the two types is similar, and both deliver approximately the same impact blow, but the drilling jar is built such that it can better withstand the rotary and vibrational loading associated with drilling.

2. [Well Completions]

A downhole tool that is used to impart a heavy blow or impact load to a downhole tool assembly. Commonly used in fishing operations to free stuck objects, jars are available in a range of sizes and capacities to deliver upward or downward impact loads. Some slickline tool assemblies use jars to operate tools that contain shear pins or spring profiles in their operating method.

3. [Well Workover and Intervention]

A downhole tool used to deliver an impact force to the tool string, usually to operate downhole tools or to dislodge a stuck tool string. Jars of different designs and operating principles are commonly included on slickline, coiled tubing and workover tool strings. Simple slickline jars incorporate an assembly that allows some free travel within the tool to gain momentum for the impact that occurs at the end of the stroke. Larger, more complex jars for coiled tubing or workover strings incorporate a trip or firing mechanism that prevents the jar from operating until the desired tension is applied to the string, thus optimizing the impact delivered. Jars are designed to be reset by simple string manipulation and are capable of repeated operation or firing before being recovered from the well.

Table 2 Jarring Loads of the Drilling Jar unit: KN

|

model |

upward jarring load |

Up jarring unlock force |

ex-plant downward jarring load |

hydraulic load testing pulling force |

Time of the Hydraulic delay |

|

JYQ121Ⅱ |

250 |

200±25 |

120±25 |

220±10 |

30~60 |

|

JYQ140 |

450 |

250±25 |

150±25 |

300±10 |

45~90 |

|

JYQ146 |

450 |

250±25 |

150±25 |

300±10 |

45~90 |

|

JYQ159 |

600 |

330±25 |

190±25 |

370±10 |

45~90 |

|

JYQ165 |

600 |

330±25 |

220±25 |

400±10 |

45~90 |

|

JYQ178 |

700 |

330±25 |

220±25 |

400±10 |

45~90 |

|

JYQ197 |

800 |

400±25 |

250±25 |

440±10 |

45~90 |

|

JYQ203 |

800 |

400±25 |

250±25 |

440±10 |

45~90 |

|

JYQ241 |

1400 |

460±25 |

260±25 |

480±10 |

60~120 |

5. SPECIFICATIONS

|

item |

JYQ121 |

JYQ140 |

JYQ146 |

JYQ159 |

JYQ165 |

|

O.D. in |

43/4 |

51/2 |

53/4 |

61/4 |

61/2 |

|

I.D in |

2 |

21/4 |

21/4 |

21/4 |

21/4 |

|

Connection API |

NC38 |

NC38 |

NC38 |

NC46 |

NC50 |

|

up jar stroke in |

9 |

9 |

9 |

9 |

9 |

|

down jar stroke in |

6 |

6 |

6 |

6 |

6 |

Continued

|

item |

JYQ178 |

JYQ197 |

JYQ203 |

JYQ241 |

| O.D. in |

7 |

7 3/4 |

8 |

9 1/2 |

| I.D in |

2 3/4 |

3 |

23/4 |

3 |

|

Connection API |

NC50 |

6 5/8REG |

65/8REG |

7 5/8REG |

|

up jar stroke in |

9 |

9 |

9 |

9 |

|

down jar stroke in |

6 |

6 |

6 |

6 |

|

working torque ft-Ibs |

22000 |

30000 |

36000 |

50000 |

|

max. tensile load lb |

540000 |

670000 |

670000 |

1200000 |

|

Max. up jar load Ib |

180000 |

224000 |

224000 |

315000 |

|

Max. down jar load Ib |

90000 |

100000 |

100000 |

112000 |

|

overall length mm |

5256 |

5096 |

5095 |

5300 |

|

piston area mm2 |

5102 |

8796 |

9170 |

17192 |

Product detail pictures:

Related Product Guide:

Our products are broadly regarded and reliable by end users and can meet up with constantly transforming financial and social requires of Hot-Selling Downhole Motor - Downhole Jar / Drilling Jars (Mechanical / Hydraulic) – VS , The product will supply to all over the world, such as: Casablanca, Spain, Frankfurt, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.