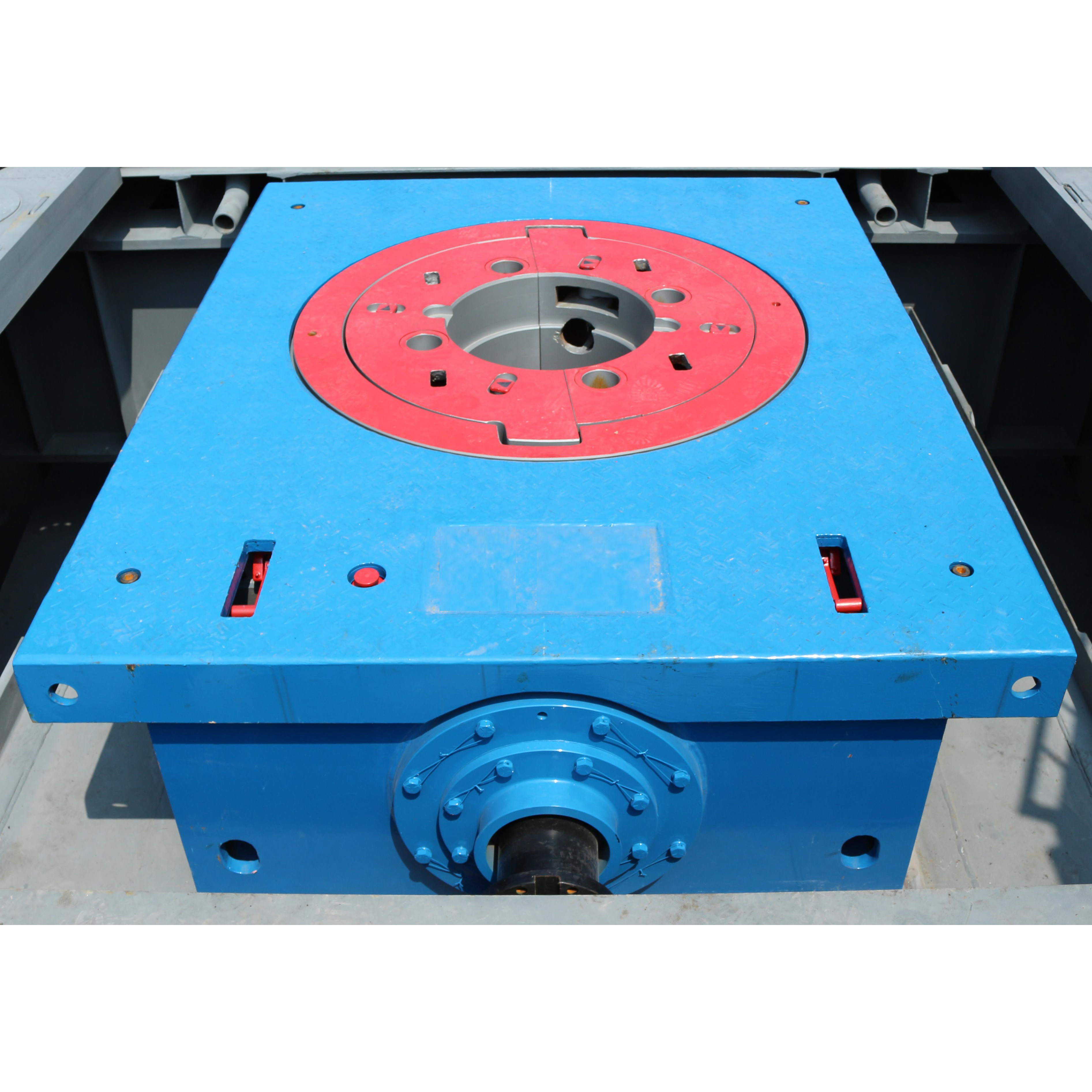

Swivel on Drilling Rig transfer drill fluid into drill string

The drilling Swivel is the main equipment for the rotary circulation of the underground operation. It is the connection between the hoisting system and the drilling tool, and the connection part between the circulation system and the rotating system. The upper part of the Swivel is hung on the hookblock through the elevator link, and is connected to the drilling hose by the gooseneck tube. The lower part is connected with the drill pipe and the downhole drilling tool, and the whole can be run up and down with the traveling block.

First, the requirements of drilling faucets for underground operations

1. The role of drilling faucets

(1) Suspension drilling tools to withstand the full weight of the downhole drilling tools.

(2) Ensure that the lower drill is free to rotate and the upper joint of the kelly does not buckle.

(3) Connected to the drilling faucet to pump high-pressure liquid into the rotating drill pipe to realize circulating drilling.

It can be seen that the drilling faucet can realize the three functions of lifting, rotation and circulation, and is an important component of rotation.

2. Requirements for drilling faucets in downhole operations

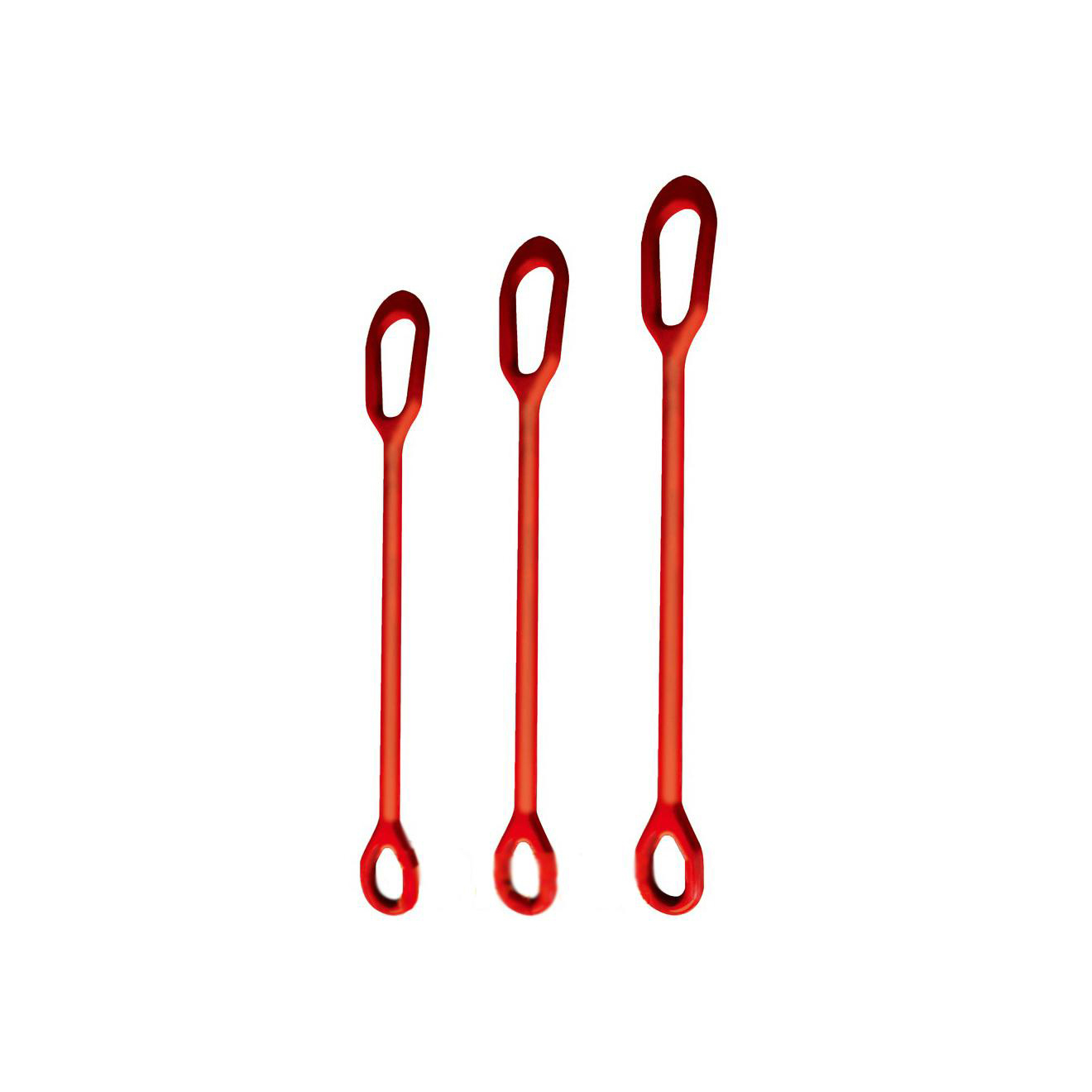

(1) The main bearing components of the drilling faucet, such as the lifting ring, the central pipe, the load bearing, etc., must have sufficient strength.

(2) The flushing assembly sealing system must have high-pressure, wear-resistant and corrosion-resistant properties, and it is convenient to replace damaged parts.

(3) The low-pressure oil seal system should be well sealed, corrosion-resistant and have a long service life.

(4) The shape and structure of the drilling faucet should be smooth and angular, and the swing angle of the lifting ring should be convenient for hanging hooks.

Technical Features:

• With optional double pin alloy steel sub.

• The wash pipe and packing device are box type integral structures and easy to replace.

• The gooseneck and the rotary hose are connected by unions or API 4LP.

Technical Parameters:

|

Model |

SL135 |

SL170 |

SL225 |

SL450 |

SL675 |

|

|

Max. static load capacity, kN(kips) |

1350(303.5) |

1700(382.2) |

2250(505.8) |

4500(1011.6) |

6750(1517.5) |

|

|

Max. speed, r/min |

300 |

300 |

300 |

300 |

300 |

|

|

Max.working pressure, MPa(ksi) |

35(5) |

35(5) |

35(5) |

35(5) |

52(8) |

|

|

Dia. of stem, mm(in) |

64(2.5) |

64(2.5) |

75(3.0) |

75(3.0) |

102(4.0) |

|

|

Joint thread |

To stem |

4 1/2"REG, LH |

4 1/2"REG, LH |

6 5/8"REG, LH |

7 5/8"REG, LH |

8 5/8"REG, LH |

|

To kelly |

6 5/8"REG, LH |

6 5/8"REG, LH |

6 5/8"REG, LH |

6 5/8"REG, LH |

6 5/8"REG, LH |

|

|

Overall dimension, mm(in) (L×W×H) |

2505×758×840 (98.6×29.8×33.1) |

2786×706×791 (109.7×27.8×31.1) |

2880×1010×1110 (113.4×39.8×43.7) |

3035×1096×1110 (119.5×43.1×43.7) |

3775×1406×1240 (148.6×55.4×48.8) |

|

|

Weight, kg(lbs) |

1341(2956) |

1834(4043) |

2815(6206) |

3060(6746) |

6880(15168) |

|

|

Note: The above-mentioned swivel have spinners (dual purpose) and no spinners. |

||||||